Products

Products

Contact Us

Tel&Whatsapp:+86-18655195022

Email:info@seriesmotionindustry.com

Add:Series Science and Technology Park, Fanhua Avenue 608 , Hefei City,China.

VRM SERIES

key word:

Category:

Cross Roller Guide

Price:

VRM SERIES

Application industry

Crossed roller guide is a high precision, high load, high rigidity linear motion track, usually used in robots, automation equipment, machining centers, precision measurement equipment and other equipment and systems that need to achieve high precision linear motion.

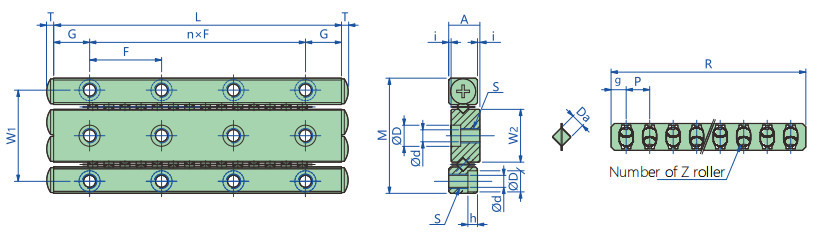

Cross roller guide: VRM1 Series

mm

| Maximum Lead | Major dimensions | |||||||||||||

| Combination dimension | lnstallation dimention | |||||||||||||

| M | A | L | n×F | i | w1 | w2 | G | S | d | D | h | T | ||

| VRM1-20×5z | 12 | 17 | 4.5 | 20 | 1×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-30×7z | 22 | 17 | 4.5 | 30 | 2×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-40×10z | 27 | 17 | 4.5 | 40 | 3×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-50×13z | 32 | 17 | 4.5 | 50 | 4×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-60×16z | 37 | 17 | 4.5 | 60 | 5×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-70×19z | 42 | 17 | 4.5 | 70 | 6×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| VRM1-80×21z | 52 | 17 | 4.5 | 80 | 7×10 | 0.5 | 13.4 | 7.8 | 5 | M2 | 1.65 | 3 | 1.4 | 0.8 |

| Retainer dimension | Basic load rating(Each roller) | ||||||

| Da | R | g | p | z | C(kN) | co(kN) | |

| VRM1-20×5z | 1.5 | 14 | 2.0 | 2.5 | 5 | 0.098 | 0.069 |

| VRM1-30×7z | 1.5 | 19 | 2.0 | 2.5 | 7 | 0.098 | 0.069 |

| VRM1-40×10z | 1.5 | 26.5 | 2.0 | 2.5 | 10 | 0.098 | 0.069 |

| VRM1-50×13z | 1.5 | 34 | 2.0 | 2.5 | 13 | 0.098 | 0.069 |

| VRM1-60×16z | 1.5 | 41.5 | 2.0 | 2.5 | 16 | 0.098 | 0.069 |

| VRM1-70×19z | 1.5 | 49 | 2.0 | 2.5 | 19 | 0.098 | 0.069 |

| VRM1-80×21z | 1.5 | 54 | 2.0 | 2.5 | 21 | 0.098 | 0.069 |

C:Basic dynamic load rating (KN) C0:Basic static load rating (KN)

| Guide | Roller | Retainer | |

| Material | Gcr15 | Gcr15 | sus304 |

| Hardness | HRC58~ | HRC60~ |

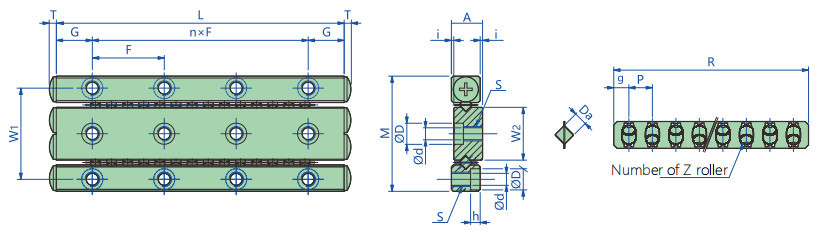

Cross roller guide VRM2 Series

mm

| Maximum Lead | Major dimensions | |||||||||||||

| Combination dimension | lnstallation dimention | |||||||||||||

| M | A | L | n×F | i | w1 | w2 | G | S | d | D | h | T | ||

| VRM2-30×5z | 18 | 24 | 6.5 | 30 | 1×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| VRM2-45×8z | 24 | 24 | 6.5 | 45 | 2×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| RM2-60×11z | 30 | 24 | 6.5 | 60 | 3×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| VRM2-75×13z | 44 | 24 | 6.5 | 75 | 4×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| VRM2-90×16z | so | 24 | 6.5 | 9o | 5×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| VRM2-105×18z | 64 | 24 | 6.5 | 105 | 6×15 | 0.5 | 19 | 11 | 7.5 | M3 | 2.5 | 4.5 l | 2 | 1.5 |

| Retainer dimension | Basic load rating(Each roller) | ||||||

| Da | R | g | p | z | C(kN) | co(kN) | |

| VRM2-30×5z | 2 | 21 | 2.5 | 4 | 5 | 0.176 | 0.127 |

| VRM2-45×8z | 2 | 33 | 2.5 | 4 | 8 | 0.176 | 0.127 |

| vRM2-60×11z | 2 | 45 | 2.5 | 4 | 11 | 0.176 | 0.127 |

| VRM2-75×13z | 2 | 53 | 2.5 | 4 | 13 | 0.176 | 0.127 |

| VRM2-90×16z | 2 | 65 | 2.5 | 4 | 16 | 0.176 | 0.127 |

| VRM2-105×18z | 2 | 73 | 2.5 | 4 | 18 | 0.176 | 0.127 |

C:Basic dynamic load rating (KN) C0:Basic static load rating (KN)

| Guide | Roller | Retainer | |

| Material | Gcr15 | Gcr15 | sus304 |

| Hardness | HRC58~ | HRC60~ |

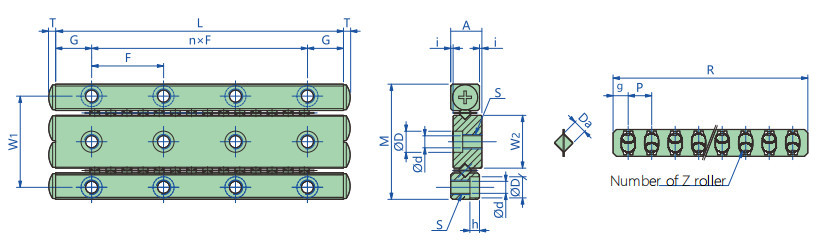

Cross roller guide VRM3 Series

mm

| Maximum Lead | Major dimensions | |||||||||||||

| Combination dimension | Installation dimention | |||||||||||||

| M | A | L | n×F | i | w1 | w2 | G | S | d | D | h | T | ||

| VRM3-50×7z | 28 | 36 | 8.5 | 50 | 1×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-75×10z | 48 | 36 | 8.5 | 75 | 2x25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-100×14z | 58 | 36 | 8.5 | 100 | 3×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-125×17z | 78 | 36 | 8.5 | 125 | 4×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-150×21z | 88 | 36 | 8.5 | 150 | 5×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-175×24Z | 108 | 36 | 8.5 | 175 | 6×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| VRM3-200×28z | 118 | 36 | 8.5 | 200 | 7×25 | 0.5 | 29 | 16.6 | 12.5 | M4 | 3.4 | 6 | 3.1 | 2 |

| Retainer dimension | Basic load rating(Each roller) | ||||||

| Da | R | g | p | z | C(kN) | co(kN) | |

| VRM3-50×7z | 3 | 36 | 3 | 5 | 7 | 0.363 | 0.275 |

| VRM3-75×10z | 3 | 51 | 3 | 5 | 10 | 0.363 | 0.275 |

| VRM3-100×14z | 3 | 71 | 3 | 5 | 14 | 0.363 | 0.275 |

| VRM3-125×17z | 3 | 86 | 3 | 5 | 17 | 0.363 | 0.275 |

| VRM3-150×21z | 3 | 106 | 3 | 5 | 21 | 0.363 | 0.275 |

| VRM3-175×24Z | 3 | 121 | 3 | 5 | 24 | 0.363 | 0.275 |

| vRM3-200×28z | 3 | 141 | 3 | 5 | 28 | 0.363 | 0.275 |

C:Basic dynamic load rating (KN) C0:Basic static load rating (KN)

| Guide | Roller | Retainer | |

| Material | Gcr15 | Gcr15 | sus304 |

| Hardness | HRC58~ | HRC60~ |

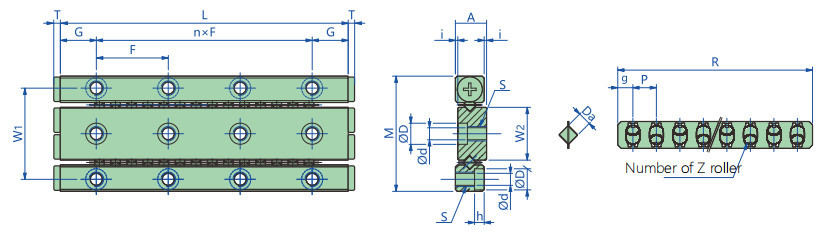

Cross roller guide VRM4 Series

mm

| Maximum Lead | Major dimensions | |||||||||||||

| Combination dimension | Installation dimention | |||||||||||||

| M | A | L | n×F | i | w1 | w2 | G | S | d | D | h | T | ||

| VRM4-80×7z | 58 | 44 | 11.5 | 80 | 1×40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| VRM4-120×11z | 82 | 44 | 11.5 | 120 | 2x40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| VRM4-160×15z | 106 | 44 | 11.5 | 160 | 3×40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| VRM4-200×19z | 130 | 44 | 11.5 | 200 | 4×40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| VRM4-240×23z | 154 | 44 | 11.5 | 240 | 5×40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| VRM4-280×27z | 178 | 44 | 11.5 | 280 | 6×40 | 0.5 | 35 | 20 | 20 | M5 | 4.3 | 8 | 4.2 | 2 |

| Retainer dimension | Basic load rating(Each roller) | ||||||

| Da | R | g | p | z | C(kN) | co(kN) | |

| VRM4-80×7z | 4 | 51 | 4.5 | 7 | 7 | 0.764 | 0.637 |

| VRM4-120×11z | 4 | 79 | 4.5 | 7 | 11 | 0.764 | 0.637 |

| VRM4-160×15z | 4 | 107 | 4.5 | 7 | 15 | 0.764 | 0.637 |

| VRM4-200×19z | 4 | 135 | 4.5 | 7 | 19 | 0.764 | 0.637 |

| VRM4-240×23z | 4 | 163 | 4.5 | 7 | 23 | 0.764 | 0.637 |

| VRM4-280×27z | 4 | 191 | 4.5 | 7 | 27 | 0.764 | 0.637 |

C:Basic dynamic load rating (KN) C0:Basic static load rating (KN)

| Guide | Roller | Retainer | |

| Material | Gcr15 | Gcr15 | sus304 |

| Hardness | HRC58~ | HRC60~ |

Application industry

Crossed roller guide is a high precision, high load, high rigidity linear motion track, usually used in robots, automation equipment, machining centers, precision measurement equipment and other equipment and systems that need to achieve high precision linear motion.

Cross Roller Guide

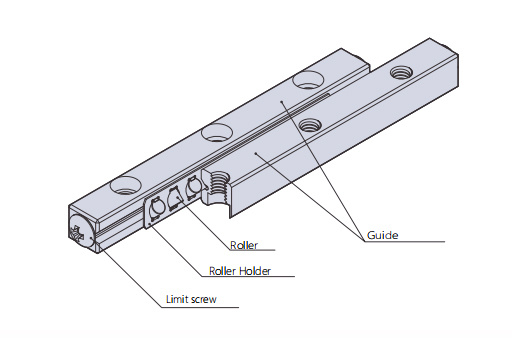

Product structure

In the VR type, the roller cage in which the precision rollers are orthogonally combined with each other is used in combination with the V-groove raceway provided on the dedicated track.By assembling two rows of roller guide rails in parallel, the rail system can withstand loads in four directions. In addition, since a preload can be applied to the cross-roller guide, a carriage mechanism with no clearance, high rigidity, and smooth movement can be obtained. Cross-roller guides are widely used in office equipment and peripheral equipment, various measuring instruments, precision equipment such as printed circuit board drilling machines, and slide parts of optical testers, optical tables, manipulation mechanisms, and X-ray devices.

Product features

●Long service life and high rigidity

Using the unique roller holding method, the effective contact length of the rollers has been increased by 1.7 times compared with the previous product, and the pitch interval of the rollers has been shortened, the number of rollers has been increased, and the rigidity has been increased by 2 times, which can obtain 6 times. lifespan. Therefore, it is possible to adequately design safety considerations for vibration and shock problems that are likely to occur in linear motion parts.

●Smooth movement

In the VR type, the roller cages are separated. Since the roller pockets in the cage are in contact with the roller surfaces, there is good lubricating oil retention, so there is no wear and friction, and smooth rolling motion can be obtained

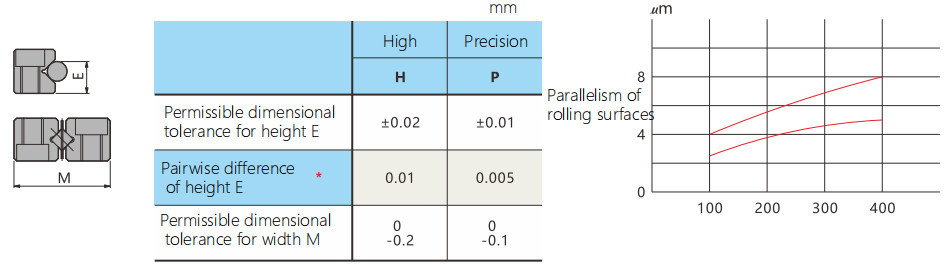

Product accuracy

The accuracy of the rail dedicated to the Cross Roller Guide is divided into high grade (H) and precision grade (P) as shown in the table below

※Pairwise mutual difference of height E for 4 tracks used on the same plane

Inquiry

Exclusive Customization Welcome Online Appointment

* Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible