Products

Products

Contact Us

Tel&Whatsapp:+86-18655195022

Email:info@seriesmotionindustry.com

Add:Series Science and Technology Park, Fanhua Avenue 608 , Hefei City,China.

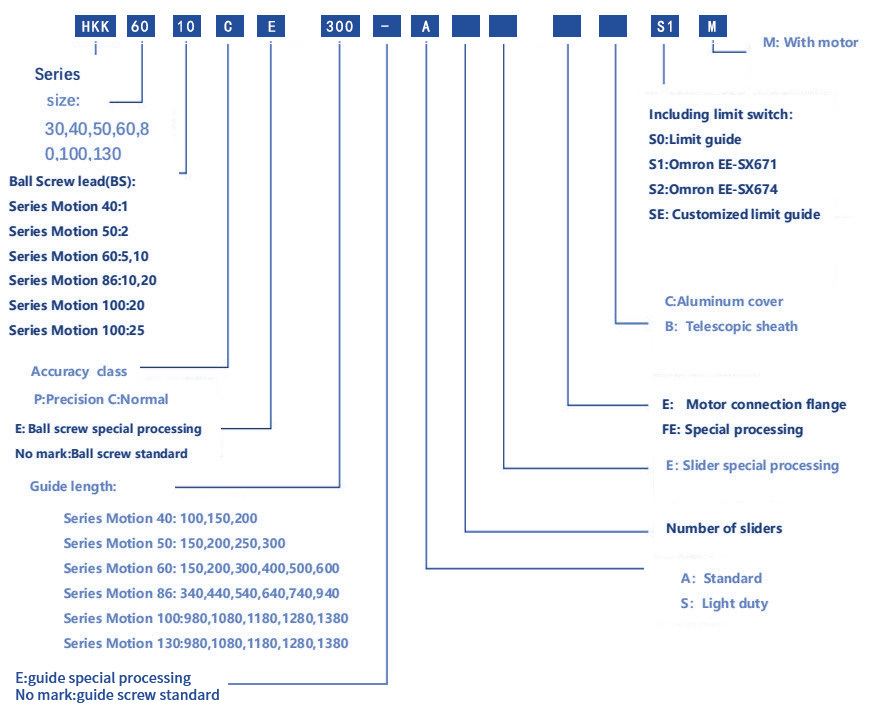

Single-axis robot

key word:

Category:

Single-axis Robot

Price:

Single-axis robot

Application industry

K-K module is a precision transmission device mainly used in machine tools and automation equipment to achieve high precision and rigid rotary motion. Due to its high precision, high load, high speed, low noise and low friction characteristics, K-K modules are widely used in several industries, including but not limited to the following:

Machine tool manufacturing industry: K-K modules are applied to various high-precision machine tools, such as CNC milling machines, CNC grinding machines, CNC lathes, etc., and are used to realize the rotary motion of machine tools.

Automated production lines: K-K modules are used in the rotation control systems on automated production lines, such as material handling, assembly and packaging, and other production line operations.

Automobile manufacturing industry: K-K modules are applied to all kinds of equipment and machines in automobile manufacturing lines, such as body assembly lines, engine assembly lines, etc., and are used to achieve rotary motion.

Aerospace manufacturing industry: K-K modules are used in various aerospace manufacturing equipment, such as aircraft parts processing equipment, rocket engine assembly equipment, etc., for achieving rotary motion.

Electronics manufacturing industry: K-K modules are used in the manufacturing of various precision electronic devices, such as LCD monitors, cell phones, digital cameras, etc., to achieve rotary motion.

In short, K-K modules are suitable for industries that need to realize high precision, high load, high speed, low noise and low friction rotary motion control systems, mainly used in machine tool manufacturing, automated production lines, automotive manufacturing, aerospace manufacturing and electronics manufacturing.

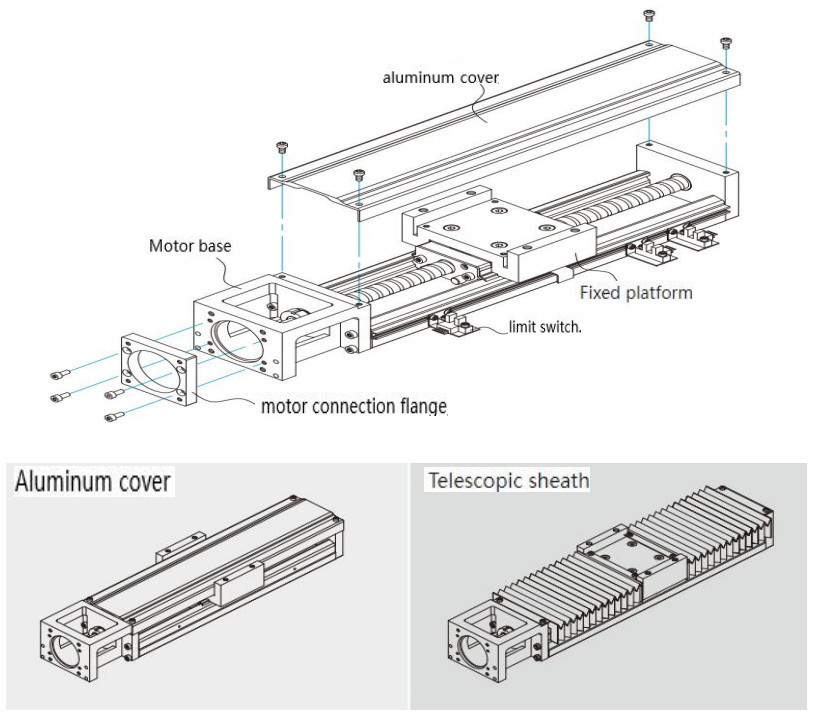

Optional accessories

In order to meet various needs, industrial robots can additionally purchase aluminum cover, telescopic sheath,motor connection flange, limit switch.

● Aluminum cover, telescopic sheath: can prevent foreign objects and impurities from entering the interior of the industrial robot and affect its service life, accuracy and smoothness.

● Motor connection flange: Various motors can be locked on the industrial robot.

● Limit Switch: Provides slider positioning, starting origin, and a safety mechanism to prevent slider overtravel

Load specification

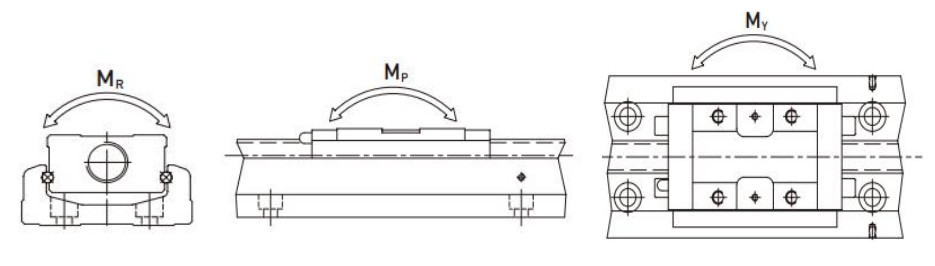

Parameters

| Type | Ball screw | Linear guide | |||||||||||||||||||

| Dia Shaft (mm) | Lead (mm) | Dynamic Ca (N) | Static Coa (N) | Dynamic Ca(N) | Dynamic Ca(N) | Allowable static resistance | |||||||||||||||

|

Slider A |

Slider S |

Slider A |

Slider S |

MP(N-m) | MY(N-m) | MR(N-m) | |||||||||||||||

| Slider A1 | Slider A2 | Slider S1 | Slider S2 | Slider A1 | Slider A2 | Slider S1 | Slider S2 | Slider A1 | Slider A2 | Slider S1 | Slider S2 | ||||||||||

|

Series Motion 4001 |

Precision |

8 | 1 | 735 | 1538 | 3920 | -- | 6468 | -- | 33 | 182 | -- | -- | 33 | 182 | -- | -- | 81 | 162 | -- | -- |

| Series Motion 4001 |

Normal |

8 | 1 | 676 | 1284 | 3920 | -- | 6468 | -- | 33 | 182 | -- | -- | 33 | 182 | -- | -- | 81 | 162 | -- | -- |

|

Series Motion 5002 |

Precision |

8 | 2 | 2136 | 3468 | 8007 | -- | 12916 | -- | 116 | 545 | -- | -- | 116 | 545 | -- | -- | 222 | 444 | -- | -- |

| Series Motion 5002 |

Normal |

8 | 2 | 1813 | 2910 | 8007 | -- | 12916 | -- | 116 | 545 | -- | -- | 116 | 545 | -- | -- | 222 | 444 | -- | -- |

|

Series Motion 6005 |

Precision |

12 | 5 | 3744 | 6243 | 13230 | 7137 | 21462 | 11574 | 152 | 348 | 72 | 205 | 152 | 348 | 72 | 205 | 419 | 838 | 241 | 482 |

| Series Motion 6005 |

Normal |

12 | 5 | 3377 | 5625 | 13230 | 7137 | 21462 | 11574 | 152 | 348 | 72 | 205 | 152 | 348 | 72 | 205 | 419 | 838 | 241 | 482 |

| Series Motion 6010 |

Precision |

12 | 10 | 2410 | 3743 | 13230 | 7137 | 21462 | 11574 | 152 | 348 | 72 | 205 | 152 | 348 | 72 | 205 | 419 | 838 | 241 | 482 |

| Series Motion 6010 |

Normal |

12 | 10 | 2107 | 3234 | 13230 | 7137 | 21462 | 11574 | 152 | 348 | 72 | 205 | 152 | 348 | 72 | 205 | 419 | 838 | 241 | 482 |

| Series Motion 8610 |

Precision |

15 | 10 | 7144 | 12644 | 31548 | 21051 | 50674 | 29475 | 622 | 3050 | 166 | 1309 | 622 | 3050 | 166 | 1309 | 1507 | 3014 | 847 | 1694 |

| Series Motion 8610 |

Normal |

15 | 10 | 6429 | 11387 | 31548 | 21051 | 50674 | 29475 | 622 | 3050 | 166 | 1309 | 622 | 3050 | 166 | 1309 | 1507 | 3014 | 847 | 1694 |

| Series Motion 8620 |

Precision |

15 | 20 | 4645 | 7655 | 31548 | 21051 | 50674 | 29475 | 622 | 3050 | 166 | 1309 | 62 | 3050 | 166 | 1309 | 1507 | 3014 | 847 | 1694 |

| Series Motion 8620 | Normal | 15 | 20 | 4175 | 6889 | 31548 | 21051 | 50674 | 29475 | 622 | 3050 | 166 | 1309 | 62 | 3050 | 166 | 1309 | 1507 | 3014 | 847 | 1694 |

| Series Motion 8620 | Normal | 15 | 20 | 4782 | 9163 | 31548 | 21051 | 50674 | 29475 | 622 | 3050 | 166 | 1309 | 62 | 3050 | 166 | 1309 | 1507 | 3014 | 847 | 1694 |

Accuracy class

| TYPE | Guide length | Localization reproducibility | Positioning accuracy | walking parallel ism | Maximum starting torque (N-cm) | ||||

| Precision | Normal | Precision | Normal | Precision | Normal | Precision | Normal | ||

| Series Motion40 | 100 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 1.2 | 0.8 |

| Series Motion40 | 150 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 1.2 | 0.8 |

| Series Motion40 | 200 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 1.2 | 0.8 |

| Series Mot | 150 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 4 | 2 |

| Series Mot | 200 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 4 | 2 |

| Series Mot | 250 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 4 | 2 |

| Series Mot | 300 | ±0.003 | ±0.005 | 0.020 | -- | 0.010 | -- | 4 | 2 |

| Series Mot | 150 | ±0.003 | ±0.005 | 0.025 | -- | 0.010 | -- | 15 | 7 |

| Series Mot | 200 | ±0.003 | ±0.005 | 0.025 | -- | 0.010 | -- | 15 | 7 |

| Series Mot | 300 | ±0.003 | ±0.005 | 0.025 | -- | 0.010 | -- | 15 | 7 |

| Series Mot | 400 | ±0.003 | ±0.005 | 0.025 | -- | 0.010 | -- | 15 | 7 |

| Series Mot | 500 | ±0.003 | ±0.005 | 0.025 | -- | 0.010 | -- | 15 | 7 |

| Series Mot | 600 | ±0.003 | ±0.005 | 0.025 | -- | 0.015 | -- | 15 | 7 |

| Series Mot | 340 | ±0.003 | ±0.005 | 0.030 | -- | 0.015 | -- | 15 | 10 |

| Series Mot | 440 | ±0.003 | ±0.005 | 0.030 | -- | 0.015 | -- | 15 | 10 |

| Series Mot | 540 | ±0.003 | ±0.005 | 0.030 | -- | 0.015 | -- | 15 | 10 |

| Series Mot | 640 | ±0.003 | ±0.005 | 0.030 | -- | 0.015 | -- | 15 | 10 |

| Series Mot | 740 | ±0.003 | ±0.005 | 0.040 | -- | 0.020 | -- | 17 | 10 |

| Series Mot | 940 | ±0.003 | ±0.005 | 0.035 | -- | 0.030 | -- | 25 | 10 |

| Series Mot | 980 | ±0.005 | ±0.01 | 0.035 | -- | 0.025 | -- | 17 | 12 |

| Series Mot | 1080 | ±0.005 | ±0.01 | 0.035 | -- | 0.025 | -- | 17 | 12 |

| Series Mot | 1180 | ±0.005 | ±0.01 | 0.040 | -- | 0.03 | -- | 20 | 12 |

| Series Mot | 1280 | ±0.005 | ±0.01 | 0.045 | -- | 0.035 | -- | 23 | 15 |

| Series Mot | 1380 | ±0.005 | ±0.01 | 0.05 | -- | 0.04 | -- | 25 | 15 |

| Series Mot | 980 | ±0.005 | ±0.01 | 0.035 | -- | 0.025 | -- | 25 | 15 |

| Series Mot | 1180 | ±0.005 | ±0.01 | 0.04 | -- | 0.03 | -- | 25 | 15 |

| Series Mot | 1380 | ±0.005 | ±0.01 | 0.04 | -- | 0.03 | -- | 25 | 15 |

| Series Mot | 1680 | ±0.007 | ±0.012 | 0.05 | -- | 0.04 | -- | 27 | 18 |

Series Motion

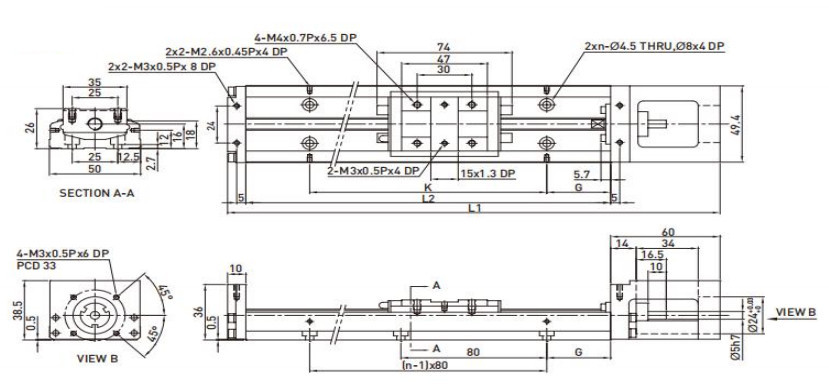

Series Motion 40(without cover)

| Guide length(L2) | Total length (L1) | Max length(mm) | G(mm) | n | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | ||||

| 100 | 159 | 36 | -- | 20 | 2 | 0.48 | -- |

| 150 | 209 | 86 | 34 | 15 | 3 | 0.6 | 0.67 |

| 200 | 259 | 136 | 84 | 40 | 3 | 0.72 | 0.79 |

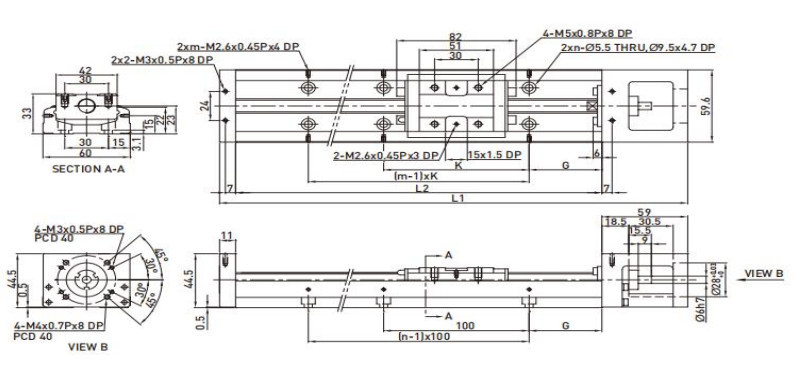

Series Motion 50(without cover)

| Guide length(L2) | Total length (L1) | Maximum stroke(mm) | G(mm) | K(mm) | n | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | |||||

| 150 | 220 | 70 | -- | 35 | 80 | 2 | 1 | -- |

| 200 | 270 | 120 | 55 | 20 | 160 | 3 | 1.2 | 1.4 |

| 250 | 320 | 170 | 105 | 15 | 160 | 3 | 1.4 | 1.6 |

| 300 | 370 | 220 | 155 | 30 | 240 | 4 | 1.6 | 1.8 |

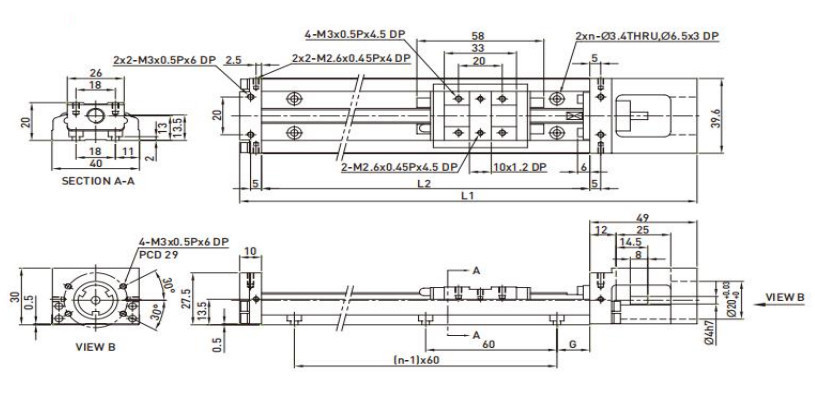

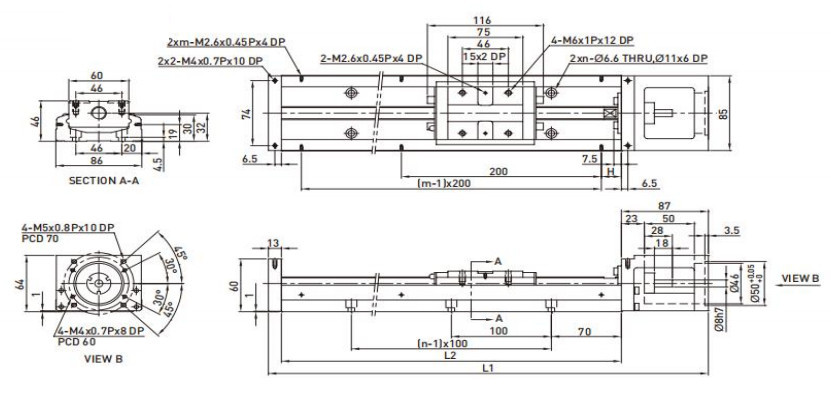

Series Motion 60(without cover)

| Guide length(L2) | Total length (L1) | Maximum stroke(mm) | G(mm) | K(mm) | n | m | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | ||||||

| 150 | 220 | 60 | -- | 25 | 100 | 2 | 2 | 1.5 | -- |

| 200 | 270 | 110 | -- | 50 | 100 | 2 | 2 | 1.8 | -- |

| 300 | 370 | 210 | 135 | 50 | 200 | 3 | 3 | 2.4 | 2.7 |

| 400 | 470 | 310 | 235 | 50 | 100 | 4 | 4 | 3 | 3.3 |

| 500 | 570 | 410 | 335 | 50 | 200 | 5 | 5 | 3.6 | 3.9 |

| 600 | 670 | 510 | 435 | 50 | 100 | 6 | 6 | 4.2 | 4.6 |

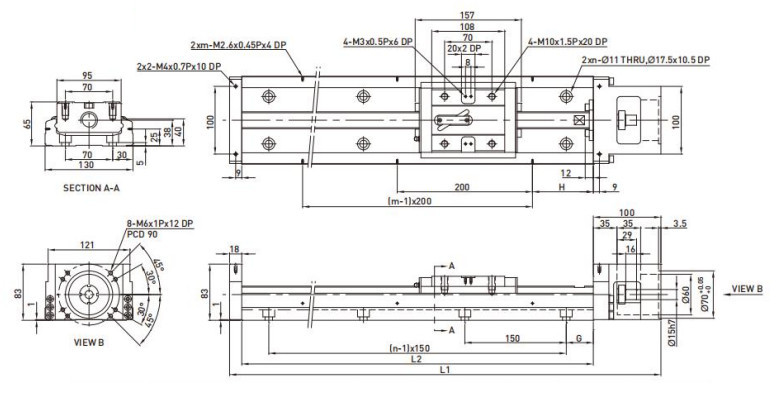

Series Motion 86(without cover)

| Guide length(L2) | Total length (L1) | Maximum stroke(mm) | H(mm) | n | m | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | |||||

| 340 | 440 | 216.5 | 108.5 | 70 | 3 | 2 | 5.7 | 6.5 |

| 440 | 540 | 316.5 | 208.5 | 20 | 4 | 3 | 6.9 | 7.7 |

| 540 | 640 | 416.5 | 308.5 | 70 | 5 | 3 | 8.0 | 8.8 |

| 640 | 740 | 516.5 | 408.5 | 20 | 6 | 4 | 9.2 | 10.0 |

| 740 | 840 | 616.5 | 508.5 | 70 | 7 | 4 | 10.4 | 11.2 |

| 940 | 1040 | 816.5 | 708.5 | 70 | 9 | 5 | 11.6 | 12.4 |

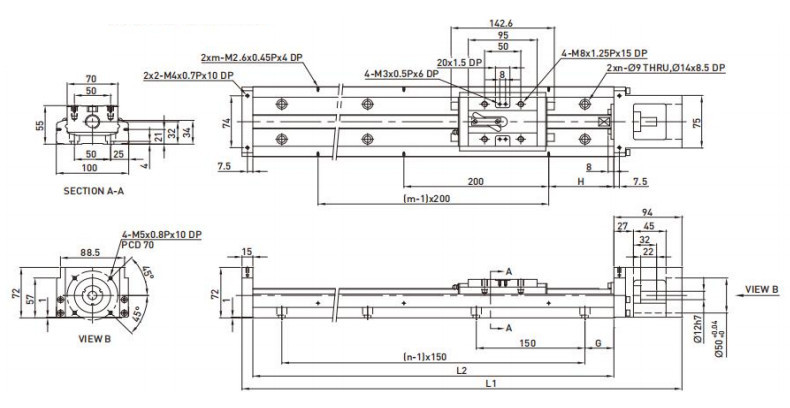

Series Motion 100(without cover)

| Guide length(L2) | Total length (L1) | Maximum stroke(mm) | G(mm) | H(mm) | n | m | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | ||||||

| 980 | 1089 | 828 | 700 | 40 | 90 | 7 | 5 | 18.6 | 20.3 |

| 1080 | 1189 | 928 | 800 | 15 | 40 | 8 | 6 | 20.3 | 22.0 |

| 1180 | 1289 | 1028 | 900 | 65 | 90 | 8 | 6 | 22.0 | 23.7 |

| 1280 | 1389 | 1128 | 1000 | 40 | 40 | 9 | 7 | 23.6 | 25.3 |

| 1380 | 1489 | 1228 | 1100 | 15 | 90 | 10 | 7 | 25.3 | 27.0 |

Series Motion130(Without Cover)

| Guide length(L2) | Total length (L1) | Maximum stroke(mm) | G(mm) | H(mm) | n | m | Weight(Kg) | ||

| A1 slider | A2 slider | A1 slider | A2 slider | ||||||

| 980 | 1098 | 811 | 659 | 40 | 90 | 7 | 5 | 29.4 | 32.3 |

| 1180 | 1298 | 1011 | 859 | 65 | 90 | 8 | 6 | 34.3 | 37.2 |

| 1380 | 1498 | 1211 | 1059 | 90 | 90 | 9 | 7 | 39.2 | 42.1 |

| 1680 | 1798 | 1511 | 1359 | 90 | 40 | 911 | 9 | 46.5 | 49.4 |

Inquiry

Exclusive Customization Welcome Online Appointment

* Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible